Concrete is everywhere. From sidewalks and parking garages to bridges and stadiums, it’s one of the most widely used construction materials in the world. But there’s one big misconception many people have about it: that concrete “dries” to become hard.

In reality, concrete doesn’t dry. It cures. And understanding the difference is essential for building structures that are safe, strong, and built to last.

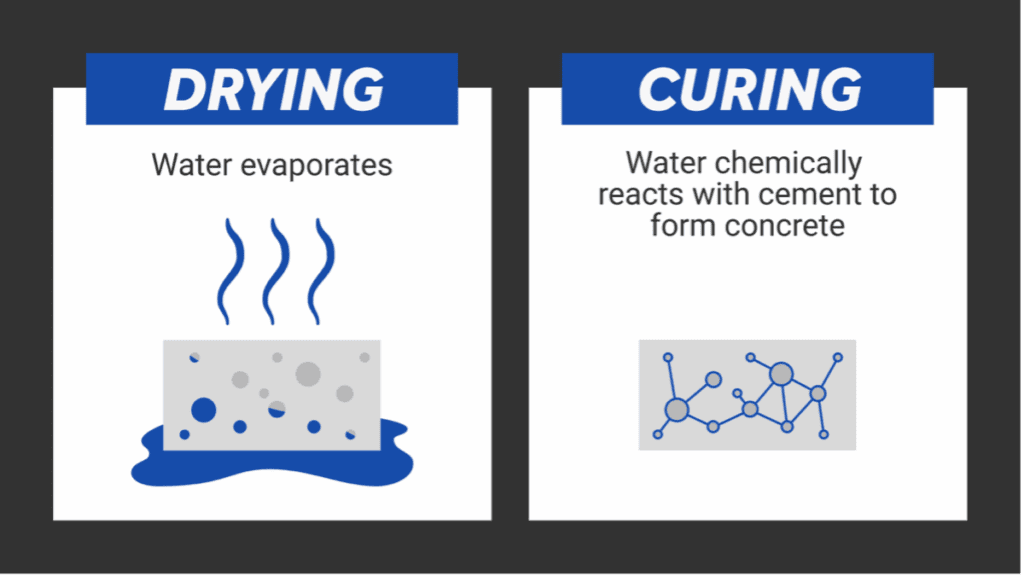

What’s the Difference Between Drying and Curing?

When most materials harden, they do so by drying. Paint dries as its liquid evaporates. Glue hardens when its moisture content is gone.

Concrete, on the other hand, hardens through a chemical process called hydration. Water reacts with cement to form calcium-silicate-hydrate (C-S-H), the compound that gives concrete its strength.

This reaction requires moisture to stay present inside the concrete for several days after placement. If the water evaporates too early, the concrete will not fully hydrate, and that leads to long-term problems.

According to the American Concrete Institute (ACI 308R-01), curing is the process of maintaining moisture and temperature conditions in freshly placed concrete to allow for proper hydration of the cement.

How is Concrete Cured?

Curing is all about keeping concrete moist and within the right temperature range so the hydration process can continue uninterrupted. There are several effective methods, each suited for different job types and environments:

- Wet coverings

Materials like burlap or cotton mats are soaked with water and placed over the surface to retain moisture. - Plastic sheets

These coverings form a barrier to keep water from evaporating. - Curing compounds

Spray-applied products that seal the surface and hold in moisture. - Fogging or misting

Used in high-heat or low-humidity conditions to maintain surface moisture. - Indoor curing

Used in precast and prestressed concrete plants where curing takes place in a controlled environment.

ASTM C511 and C31 standards outline industry-approved practices for maintaining ideal conditions during the curing period.

The Results of Improper vs. Proper Curing

What Happens When Concrete Is Not Cured Properly?

When concrete loses moisture too early, the hydration reaction stops. This leads to:

- Surface cracking due to shrinkage or thermal stress

- Reduced strength, especially in tension zones

- Increased porosity, which allows water and chemicals to penetrate

- Shorter lifespan, requiring more frequent repairs or replacements

Poor curing might not be obvious at first glance, but over time it leads to visible and structural failures.

What Happens When Concrete Is Cured Properly?

With proper curing, the concrete performs as designed. You get:

- Maximum compressive strength for structural support

- Improved durability in harsh weather or chemical environments

- Better bonding with embedded reinforcement and finishes

- Lower maintenance costs over the product’s lifespan

Cured right, concrete can last for generations, especially in critical infrastructure like bridges and industrial buildings.

How We Cure Concrete at Prestressed Concrete Construction

At Prestressed Concrete, curing is not an afterthought. It is a built-in part of our production process that ensures every product meets quality and performance expectations before it ever leaves our plant.

Here’s how we do it:

- Controlled environment

Many of our products are made in spaces where temperature and moisture conditions can be consistently managed. - Moisture prevention

We use proven techniques to lock in moisture during early-stage curing. This helps prevent cracking and ensures long-term strength. - Certified strength

Every product is tested before shipment to confirm that it meets the design requirements of your project. You get reliability you can count on.

References

- American Concrete Institute (ACI). ACI 308R-01: Guide to Curing Concrete

- ASTM International. ASTM C31/C31M: Standard Practice for Making and Curing Concrete Test Specimens in the Field

- ASTM C511: Standard Specification for Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes